Our thermographic inspection service is a critical part of the preventive maintenance programs of facility managers, utility companies, manufacturers and various other businesses that rely on electrical equipment and mechanical systems for daily operations.

Detect system overloads, loose defective components and damaged switchgear. Infrared electrical testing finds hot, dangerous problems quickly.

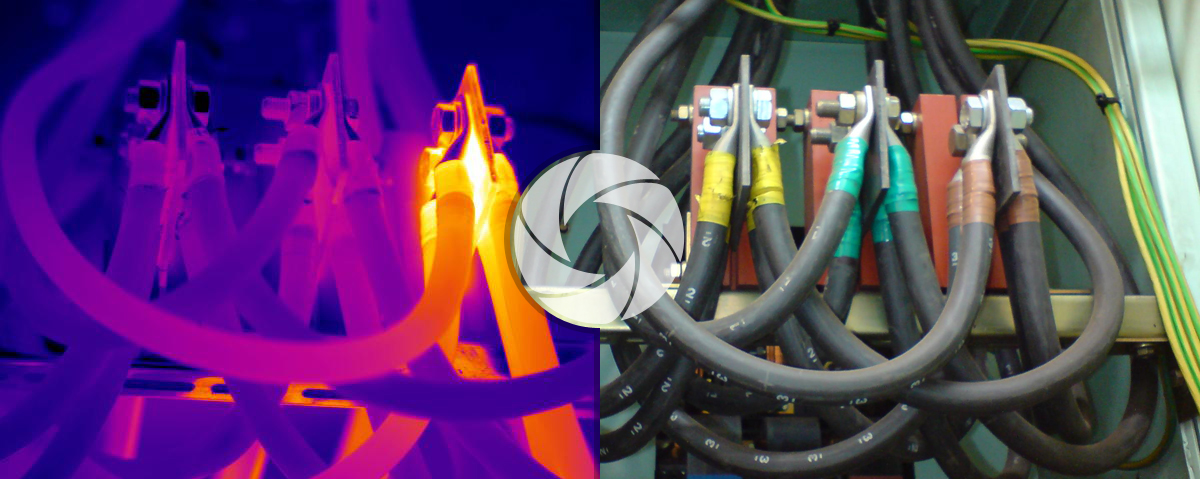

Infrared electrical inspections find hot spots caused by defects in connections and components. Infrared thermography is used to find areas of excess heat (caused by increased resistance) so that problems can be corrected before a component fails, causing damage to the component, creating safety hazards and productivity loss. Because increased heating is a sign of failure, infrared is the best diagnostic tool available for finding these hot connections in the early stages of degeneration. This is why your insurance company may have asked for an electrical infrared inspection, to find and prevent problems before they cause damage to your personnel, equipment and facility.